Top Inventory Management Techniques You Need To Know Today

Inventory management is a technique of stocking, delivering, and tracking of materials that are required in the production of a good. Inventory management techniques are customizable, and hence companies are free to adopt a mixture for best commercial results.

With efficient shipping being a critical determining factor for a business, it is imperative that an ecommerce store has an optimum inventory that is stocked and organized at all times.

Did you know, 1/3 of businesses will miss a shipment deadline because they’ve sold an item that wasn’t actually in stock.

If you’re looking for techniques to make sure you can manage your list correctly, continue reading

The significance of inventory management

Inventory management is significant for manufacturing units as it blocks cash. Keeping too little or too much inventory could be unfavorable for a company; too much stock could result in the loss as it might not be used up within a stipulated time, and too little inventory could hamper production and supply. Therefore, it is a crucial aspect of a business that needs constant intervention.

Maintaining the correct quantity of material stock is therefore crucial and involves professional guidance. It is essential to keep a flow of inventory, compared to the flow of cash for any commercial body.

Financial Benefits

Efficient inventory management is a trusted way of saving money. Many materials are perishable or get spoilt beyond a specified period. Stocking such materials in vast quantities becomes a loss if they are not used within a stipulated time.

Spoilage is a loss and is avoided through management techniques. Loss of money could also result from the creation of ‘dead stock.’ Even if materials might not perish, their usage could stop due to change in tastes and preferences of buyers.

An excellent example is still cameras. Though the components are non-perishable, they are no longer used. The identification of deadstock materials requires experienced managers.

Storage and preservation involve money. Maintaining excess stock increases not only the area of the room but also the possibility of damages. Either storage facilities need to be improved, or stock must be reduced for keeping it in a working condition. Saving the storage space ultimately leads to the saving of money.

Improves Cash Flow

Thorough knowledge about your inventory would help in the timely procurement and liquidation of materials. Regular acquisition and disbursal of stock are vital for regularising of cash flow. The forecast is critical in determining production and hence the requirement of inventory. Cash flow planning is integral to any business.

Organized Warehouse

An inventory management strategy helps you organize your warehouse and process orders faster. You can further eliminate the risk of out of stock products and help maintain a proper sync between your order management system and warehouse.

Inventory Management Techniques

There are several inventory management techniques which could be adopted depending on various situations.

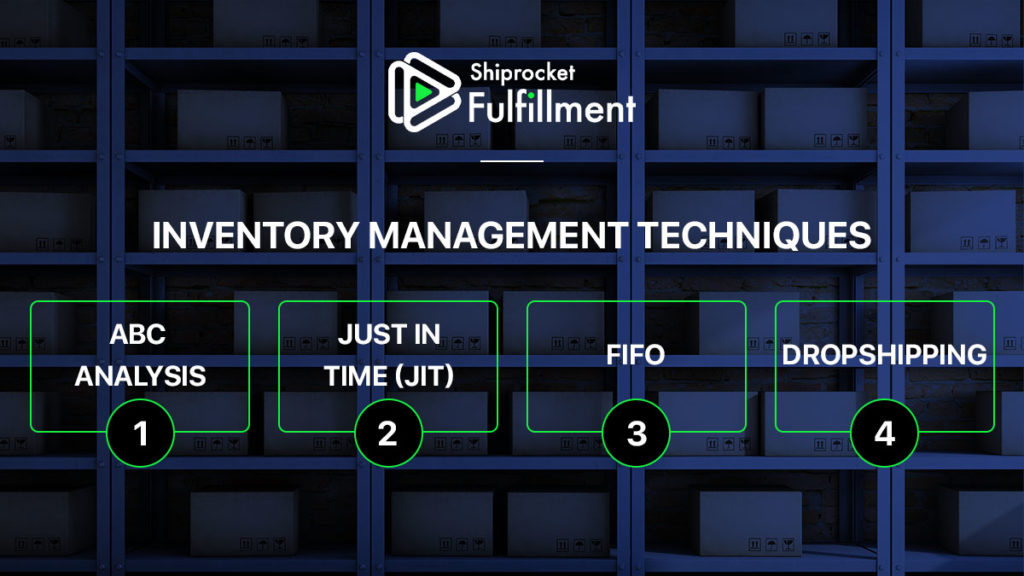

ABC Analysis

ABC or Always Better Control analysis is dependent on the classification of inventory items. ‘A’ type items are of high value but used in small quantity. ‘B’ type is of moderate value and used in moderate numbers, while ‘C’ type is of low cost but used in large quantity.

These three categories of items need differential treatment as far as storing is concerned. ‘A’ being of high value needs greater storage attention while ‘C’ requires a minimum.

Just in Time (JIT)

It is a technique that puts minimal effort into inventory. Materials are procured ‘just in time’ of production. It involves plenty of risks too, as materials could get exhausted when they may be needed most.

FIFO

This technique refers to first in first out. Applicable majorly for perishable items, it is valuable for most businesses. It is viable, fast, and helps maintain the stock for further use. With first in, first out, you can keep track of inventory and also predict when to order fresh stock.

Dropshipping

In this technique, the concept of creating an inventory is eliminated. Here, customer orders are directly routed to a producer and do not involve any intermediaries in between.

The choice of technique is market driven and could be varied depending on the existing operations. A company could even mix and match these inventory techniques as your business demands.

Final Thoughts

These techniques combined with active strategizing and management can help you plan your ecommerce business better and also give you an edge over predicting sales, managing, and shipping!